Wood grain aluminum veneer

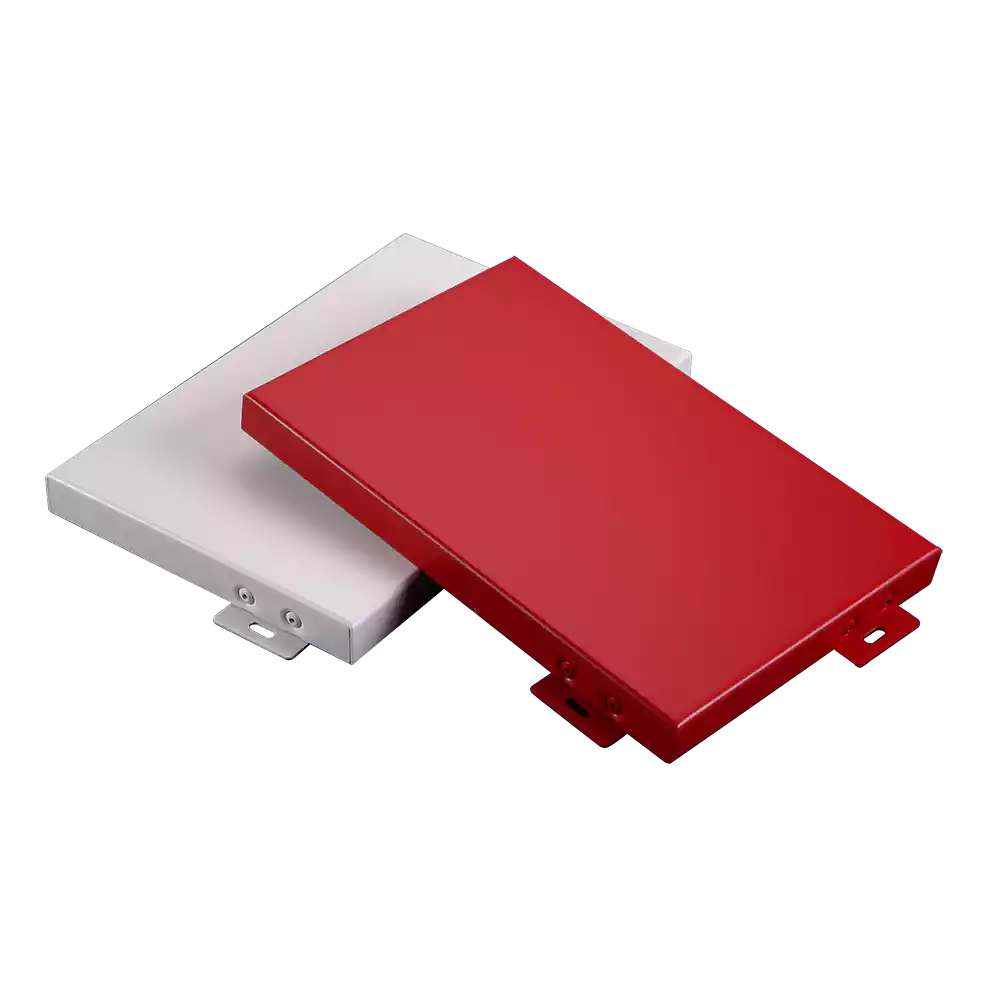

Material: Aluminum alloy (usually 3000 series or 5000 series)

Thickness: generally 1.0mm to 3.0mm

Size: Standard size is 1220mm x 2440mm, special sizes can be customized

Weight: Approximately 3.5-8.0 kg/m², depending on thickness and size

Fire resistance grade: Class A

Wind pressure resistance: in line with national building standards

Service life: up to more than 20 years

Products Description

Introduction to wood grain aluminum veneer

Wood grain aluminum veneer is a new type of building decoration material that combines the light weight and high strength of aluminum with the natural beauty of wood. It is widely used in building facades and interior decoration. Its unique wood grain effect and excellent performance make it a popular choice in modern architectural design.

parameter

Material: Aluminum alloy (usually 3000 series or 5000 series)

Thickness: generally 1.0mm to 3.0mm

Size: Standard size is 1220mm x 2440mm, special sizes can be customized

Weight: Approximately 3.5-8.0 kg/m², depending on thickness and size

Fire resistance grade: Class A

Wind pressure resistance: in line with national building standards

Service life: up to more than 20 years

application

The application range of wood grain aluminum veneer is very wide, mainly including:

Building facade: As an exterior wall decoration material, it provides good visual effects and weather resistance.

Interior decoration: used on ceilings, walls, pillars and other parts to add a natural atmosphere.

Billboards and exhibition displays: Because of its elegant appearance and easy processing characteristics, it is suitable for making various advertising and exhibition display boards.

Home decoration: used on furniture surfaces, background walls, etc. to enhance the warmth of the indoor environment.

Craftsmanship

The production process of wood grain aluminum veneer mainly includes the following steps:

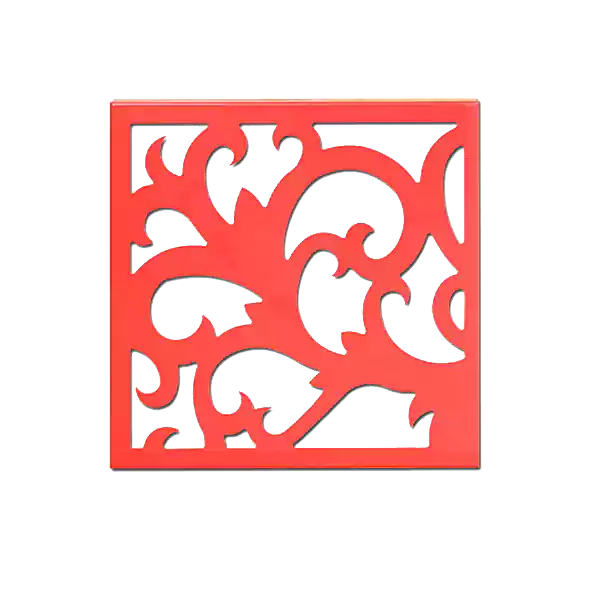

Selection and cutting of aluminum alloy materials: Select high-quality aluminum alloy and cut it according to the design requirements.

Forming: The aluminum plate is processed into the required shape through stamping, bending and other processes.

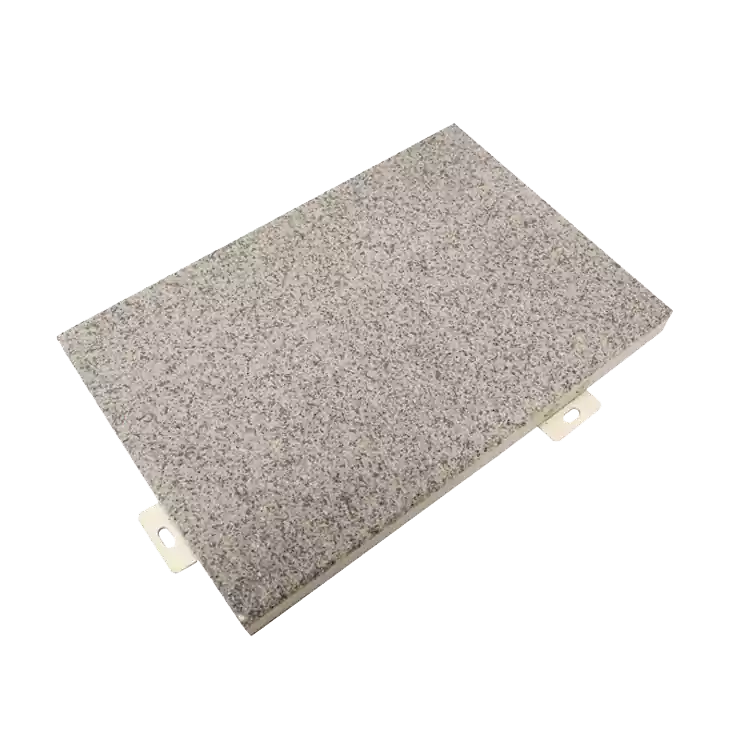

Surface treatment: Use spraying, transfer printing and other technologies to achieve wood grain effect.

Assembly and testing: Assemble the processed aluminum veneers and conduct strict quality testing to ensure that the products meet standards.

Surface treatment

The surface treatment of wood grain aluminum veneer is an important factor in its beauty and durability. Mainly include:

Spray coating: Use high weather-resistant coating to provide good adhesion and wear resistance.

Wood grain transfer: The wood grain pattern is transferred to the surface of the aluminum plate through a special process, with realistic effects and rich colors.

Anodizing: Increases the corrosion resistance and wear resistance of the aluminum plate surface and extends its service life.

PVDF coating: Provides excellent UV resistance and self-cleaning properties.

in conclusion

Wood grain aluminum veneer has become an ideal choice for modern architecture and decoration due to its light weight, high strength, weather resistance and aesthetics. With the continuous advancement of technology, its application prospects will be broader and it will be one of the important trends in future architectural design.

FAQ

Does the product support customization?

Yes, our products are all factory direct sales and can be customized according to customer needs.

What are the color options for Slatted Acoustic Panel surface?

Melamine Surface、Engineered Wood Surface、Natural Wood Surface、Baseboard Color

What is the thickness of the wood veneer of the Slatted Acoustic Panel?

Our product’s standard wood veneer thickness is 0.45mm and 0.25mm.

How many facets can a Slatted Acoustic Panel have?

Slatted Acoustic Panel has three covers and one cover.