Column-coated aluminum veneer

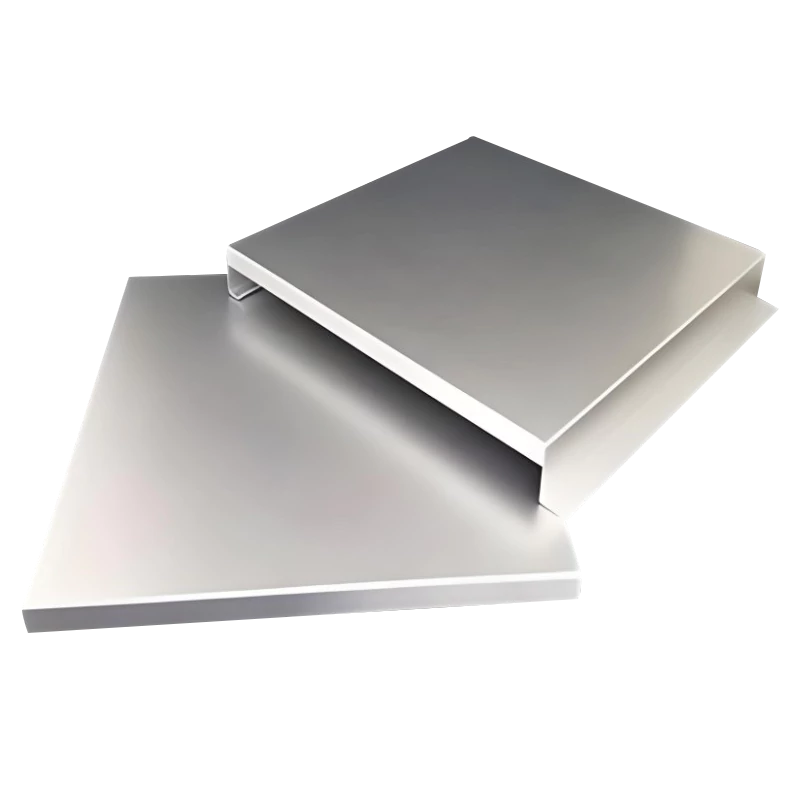

Thickness: usually between 2.0mm and 4.0mm, can be customized according to actual needs.

Material: Mainly made of 1100H24, 3003H24, 5005H24 and other aluminum alloy materials.

Surface treatment: The surface generally uses fluorocarbon spraying (PVDF) or polyester spraying (PE), with a thickness of 20μm-30μm. The fluorocarbon coating is more weather-resistant.

Specifications and dimensions: It can be customized according to the diameter and height of the column. Generally, the size of a single aluminum veneer does not exceed 1500mm × 4000mm.

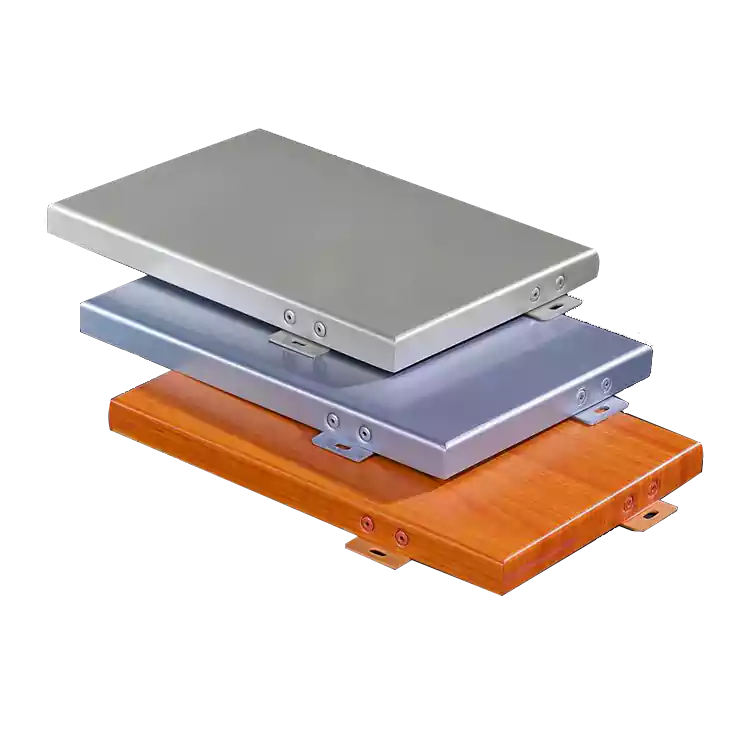

Color: The color can be customized according to RAL or PANTONE color card, or special effect colors can be produced according to specific design requirements, such as metallic color, wood grain, stone grain, etc.

Products Description

Column-clad aluminum veneer is a material used for building exterior wall decoration. Because of its excellent properties such as lightness, durability, and anti-corrosion, it is widely used in building columns, curtain walls and other areas. The following is an introduction to column-clad aluminum veneer, including its main features, parameters and application scenarios.

1. Characteristics of column-wrapped aluminum veneer

Lightweight and high-strength: Aluminum has low density and light weight, but high strength, making it suitable for exterior wall decoration of high-rise buildings.

Good weather resistance: The surface of aluminum veneer is usually spray-coated, which has good weather resistance, strong resistance to ultraviolet rays, oxidation, acid and alkali resistance, and is not easy to fade and deform.

Strong decorative effect: Column-wrapped aluminum veneer can be customized in various colors and shapes according to design needs to meet the architect’s personalized design requirements. It can also produce various effects such as wood grain and stone grain.

Easy to process and form: Aluminum veneer is easy to process and can be bent, welded and customized according to the structure of the column to meet the design requirements of different buildings.

Environmentally friendly and recyclable: Aluminum itself is a recyclable and environmentally friendly material with a long service life and can be recycled when the building is demolished or renovated.

2. Common parameters of column-wrapped aluminum veneer

Thickness: usually between 2.0mm and 4.0mm, can be customized according to actual needs.

Material: Mainly made of 1100H24, 3003H24, 5005H24 and other aluminum alloy materials.

Surface treatment: The surface generally uses fluorocarbon spraying (PVDF) or polyester spraying (PE), with a thickness of 20μm-30μm. The fluorocarbon coating is more weather-resistant.

Specifications and dimensions: It can be customized according to the diameter and height of the column. Generally, the size of a single aluminum veneer does not exceed 1500mm × 4000mm.

Color: The color can be customized according to RAL or PANTONE color card, or special effect colors can be produced according to specific design requirements, such as metallic color, wood grain, stone grain, etc.

Installation method: Using aluminum alloy keel structure and fastener connection and fixation, installation is quick and firm.

Weight: Depending on the thickness and size, the weight of a single aluminum veneer is between 8kg/m²-15kg/m².

Fire resistance: Aluminum veneer itself is a non-combustible material with excellent fire resistance and can usually reach A1 level fire protection standards.

3. Application scenarios of column-wrapped aluminum veneer

Column-clad aluminum veneers are mainly used in decorative fields such as exterior walls, porches, and column cladding of buildings. Specific applications include:

Building exterior facade columns: Especially suitable for exterior column decoration of large public buildings such as office buildings, airports, convention and exhibition centers, etc.

Indoor column decoration: In large shopping malls, hotels, conference centers and other indoor spaces, it can be used to cover columns to improve the decoration.

Landscape columns in commercial plazas and high-end residential areas: as outdoor decorative elements, integrated with the overall architectural style.

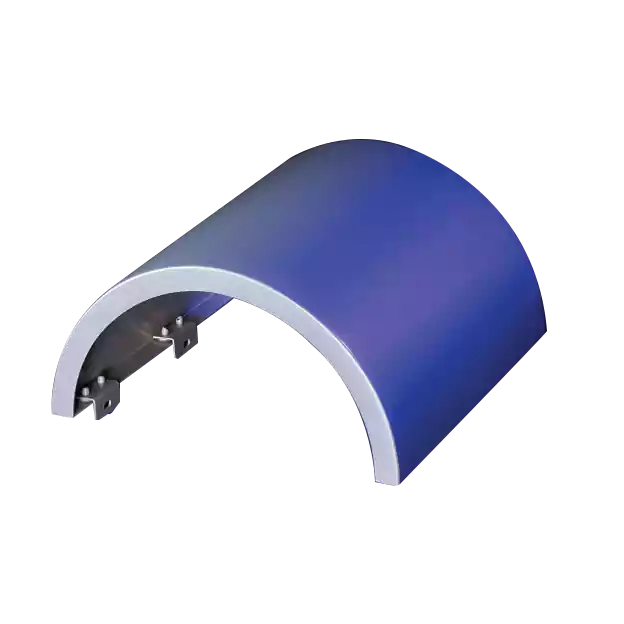

Covering decoration of special-shaped buildings: For complex building structures, aluminum veneers can be covered with curved surfaces to create a streamlined design effect.

4. Advantages of column-wrapped aluminum veneer

Strong customization: It can be highly customized according to the actual needs and design plans of the building.

Convenient construction: Due to its lightweight, column-wrapped aluminum veneer is easy to install and can greatly shorten the construction period.

High durability: It can maintain long-term beauty and practicality even in harsh climate conditions, reducing maintenance costs.

5. Conclusion

Column-clad aluminum veneer is one of the preferred materials for modern architectural decoration. With its excellent performance and flexible design applications, it has become an important exterior wall and column decoration material in the construction industry. According to different architectural styles and functional requirements, choosing the appropriate thickness, size and surface treatment technology can achieve the ideal visual effect and service life.

FAQ

Does the product support customization?

Yes, our products are all factory direct sales and can be customized according to customer needs.

What are the color options for Slatted Acoustic Panel surface?

Melamine Surface、Engineered Wood Surface、Natural Wood Surface、Baseboard Color

What is the thickness of the wood veneer of the Slatted Acoustic Panel?

Our product’s standard wood veneer thickness is 0.45mm and 0.25mm.

How many facets can a Slatted Acoustic Panel have?

Slatted Acoustic Panel has three covers and one cover.