Fluorocarbon aluminum veneer

Material: 1100H24, 3003H24, 5005H24 and other aluminum alloy materials.

Thickness: Conventional thicknesses are 2.0mm, 2.5mm, and 3.0mm (different thicknesses can be customized).

Plate size: The conventional size is 1220mm×2440mm. The length can be customized according to actual needs. The maximum length generally does not exceed 6000mm.

Coating thickness: The thickness of fluorocarbon coating is usually between 25μm and 40μm, which can be divided into two processes: two coatings and one baking, three coatings and two bakings.

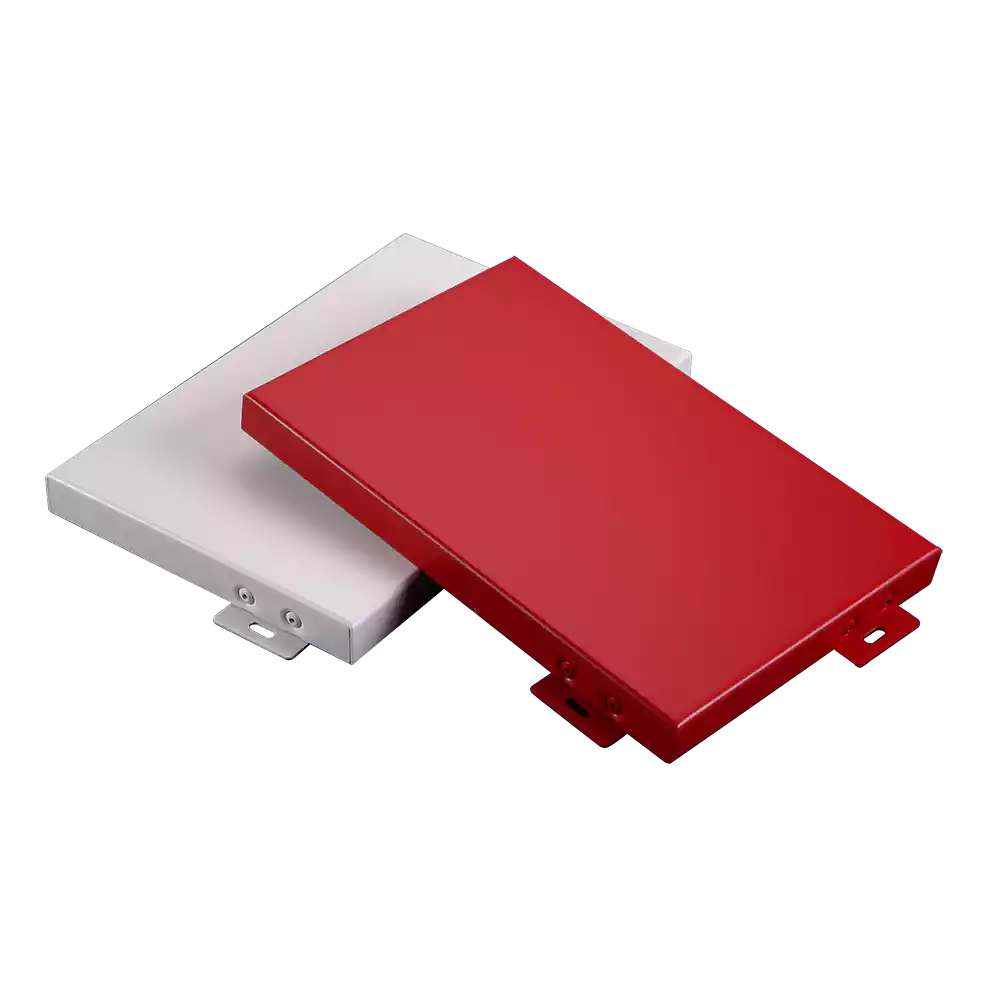

Color: Colors can be customized according to customer needs. Common colors include metallic colors, solid colors, imitation stone patterns, etc.

Surface treatment: fluorocarbon spray treatment, using polyvinylidene fluoride (PVDF) resin.

Products Description

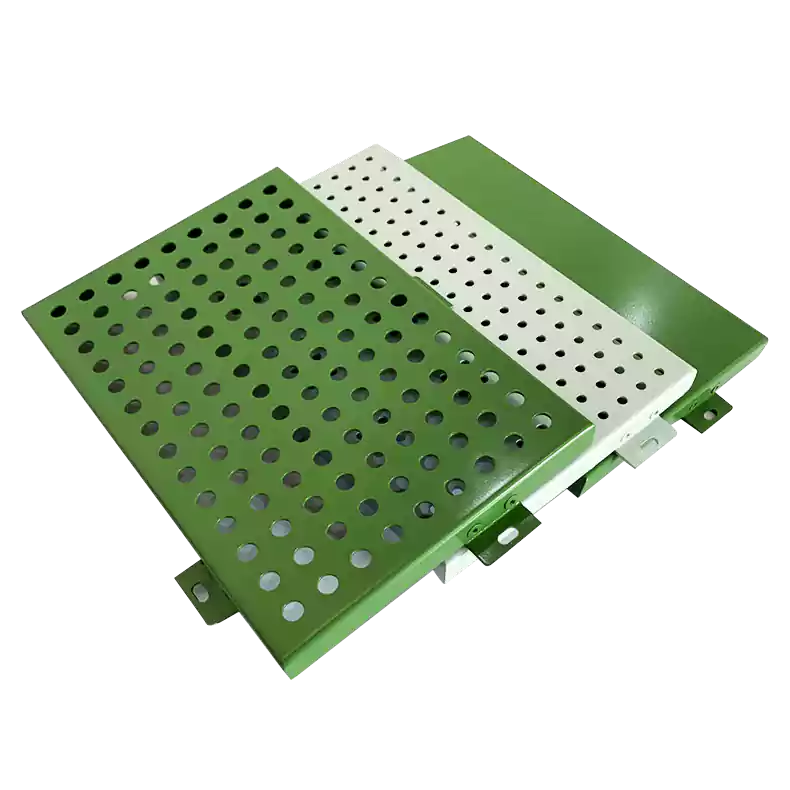

Fluorocarbon aluminum veneer is a kind of building decoration material with aluminum alloy plate as the base material and the surface treated with fluorocarbon resin coating. Because of its superior weather resistance, corrosion resistance, UV resistance and beautiful decorative effect, it is widely used in It is widely used in building exterior walls, curtain walls, ceilings and other fields.

Features of fluorocarbon aluminum veneer:

Strong weather resistance: The fluorocarbon coating has excellent UV resistance, can maintain color stability under harsh climate conditions, and is not easy to fade, powder or peel.

Good corrosion resistance: Fluorocarbon coating has strong resistance to chemical substances such as acid, alkali, salt spray, etc., and is suitable for use in coastal areas or areas with serious industrial pollution.

Light weight and high strength: Aluminum alloy material has excellent mechanical properties and is lighter in weight than steel, making it easy to transport and install.

Diverse appearance: Through different fluorocarbon coating processes, fluorocarbon aluminum veneer can present a variety of colors, textures and gloss effects, which can meet the aesthetic needs of architectural design.

Easy to process: Aluminum veneer is easy to cut, bend, punch, weld and other secondary processing, and the shape and size can be customized according to different design requirements.

Environmental protection and energy saving: Aluminum alloy can be recycled and reused, and the fluorocarbon coating itself is harmless to the environment and conforms to the concept of green environmental protection.

Common parameters:

Material: 1100H24, 3003H24, 5005H24 and other aluminum alloy materials.

Thickness: Conventional thicknesses are 2.0mm, 2.5mm, and 3.0mm (different thicknesses can be customized).

Plate size: The conventional size is 1220mm×2440mm. The length can be customized according to actual needs. The maximum length generally does not exceed 6000mm.

Coating thickness: The thickness of fluorocarbon coating is usually between 25μm and 40μm, which can be divided into two processes: two coatings and one baking, three coatings and two bakings.

Color: Colors can be customized according to customer needs. Common colors include metallic colors, solid colors, imitation stone patterns, etc.

Surface treatment: fluorocarbon spray treatment, using polyvinylidene fluoride (PVDF) resin.

Weather resistance: In the natural environment, the service life can reach more than 20 years, keeping the color unchanged.

Application fields:

Building curtain wall: used for exterior wall decoration of high-rise buildings, with good wind pressure resistance and decorative effect.

Interior decoration: often used on indoor ceilings, walls, screens, etc., to give the indoor space a sense of modernity and beauty.

Public facilities: Exterior and interior wall decoration of large-area public buildings such as airports, stations, stadiums, etc.

Fluorocarbon aluminum veneer plays an important role in modern architecture due to its durability, decoration and environmental protection characteristics, meeting the dual needs of architectural designers for the beauty and functionality of materials.

FAQ

Does the product support customization?

Yes, our products are all factory direct sales and can be customized according to customer needs.

What are the color options for Slatted Acoustic Panel surface?

Melamine Surface、Engineered Wood Surface、Natural Wood Surface、Baseboard Color

What is the thickness of the wood veneer of the Slatted Acoustic Panel?

Our product’s standard wood veneer thickness is 0.45mm and 0.25mm.

How many facets can a Slatted Acoustic Panel have?

Slatted Acoustic Panel has three covers and one cover.