Wall aluminum veneer

Light weight: The density of aluminum veneer is low, which facilitates transportation and construction and reduces the burden on the building structure.

High strength: Aluminum has good compressive and tensile strength and can withstand the impact of the external environment.

Corrosion resistance: The surface of the aluminum veneer has been anodized, which can effectively resist acid and alkali corrosion and oxidation.

Recyclability: Aluminum is recyclable and meets the requirements of sustainable development.

Products Description

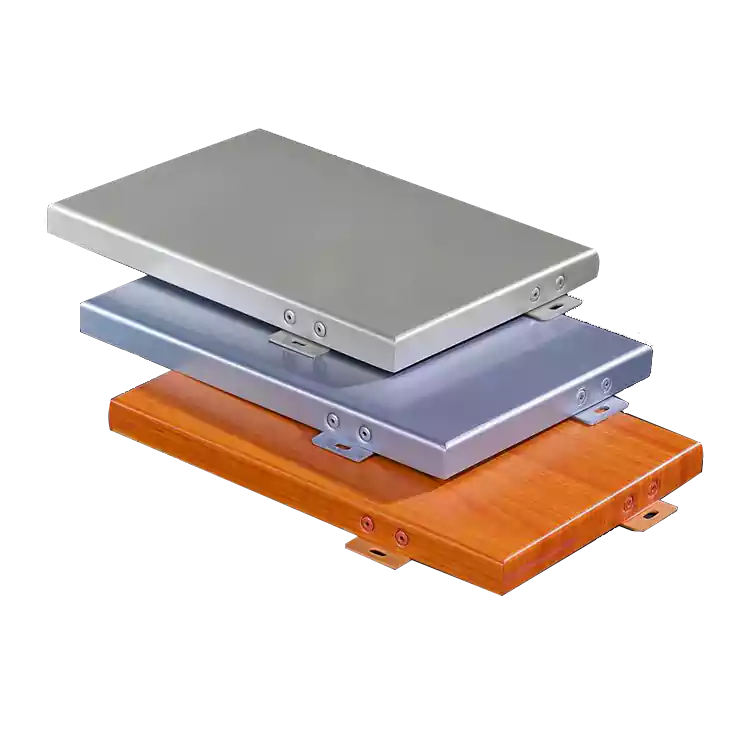

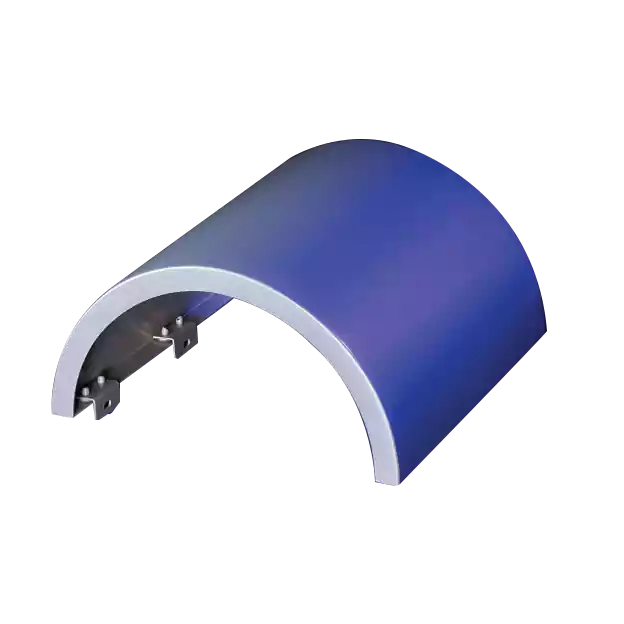

Wall aluminum veneer is a new type of building material, widely used in exterior wall decoration, interior wall partitions and other building surfaces. Due to its superior performance and diverse designs, aluminum veneer has become an indispensable part of modern architecture.

1. Material characteristics

Light weight: The density of aluminum veneer is low, which facilitates transportation and construction and reduces the burden on the building structure.

High strength: Aluminum has good compressive and tensile strength and can withstand the impact of the external environment.

Corrosion resistance: The surface of the aluminum veneer has been anodized, which can effectively resist acid and alkali corrosion and oxidation.

Recyclability: Aluminum is recyclable and meets the requirements of sustainable development.

2. Technical parameters

Thickness: usually 2mm, 3mm, 4mm, special requirements can be customized.

Size: Common size is 1200mm×2400mm, other sizes can be customized according to project requirements.

Surface treatment:

Spray coating: Fluorocarbon spray or polyester spray can be used, with various colors and smooth surface.

Wood grain film: simulates wood texture, suitable for interior decoration.

Aluminum alloy materials: Commonly used aluminum alloy models are 1050, 1100, 3003, 5005, etc. The properties of different alloys are slightly different.

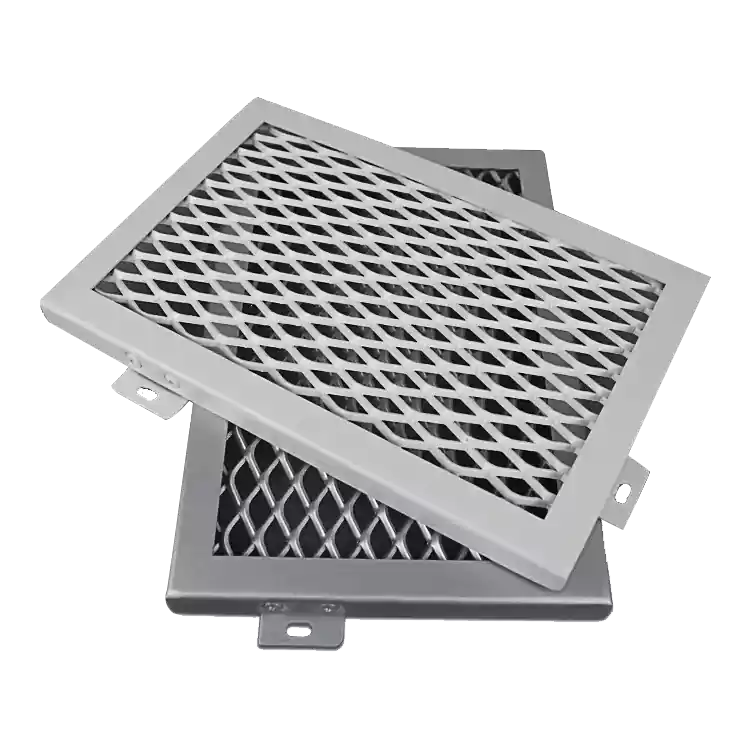

3. Application areas

Commercial buildings: exterior wall decoration of shopping malls, hotels, and office buildings.

Industrial buildings: walls and roofs of factories, warehouses, cold storage, etc.

Indoor space: partitions, ceilings, background walls, etc.

4. Construction points

Base treatment: Make sure the base is flat, clean, and able to bear the weight of the aluminum veneer.

Installation method: Various installation methods such as hanging, fixing or pasting can be used, which need to be selected according to the specific situation.

Seam treatment: Pay attention to the aesthetics and sealing of seams to avoid moisture penetration.

5. Summary of advantages

Wall aluminum veneer has become the first choice material for modern architectural decoration due to its lightness, durability and beauty. Its various surface treatments and color options provide designers with a broad creative space.

in conclusion

With the development of the construction industry, the application of wall aluminum veneers will become more widespread. Choosing the right aluminum veneer product can improve the beauty and service life of the building and meet the high standards of modern architecture.

FAQ

Does the product support customization?

Yes, our products are all factory direct sales and can be customized according to customer needs.

What are the color options for Slatted Acoustic Panel surface?

Melamine Surface、Engineered Wood Surface、Natural Wood Surface、Baseboard Color

What is the thickness of the wood veneer of the Slatted Acoustic Panel?

Our product’s standard wood veneer thickness is 0.45mm and 0.25mm.

How many facets can a Slatted Acoustic Panel have?

Slatted Acoustic Panel has three covers and one cover.