Punched aluminum veneer

Material: Aluminum alloy (commonly used aluminum alloy grades are 3003, 5052, etc.)

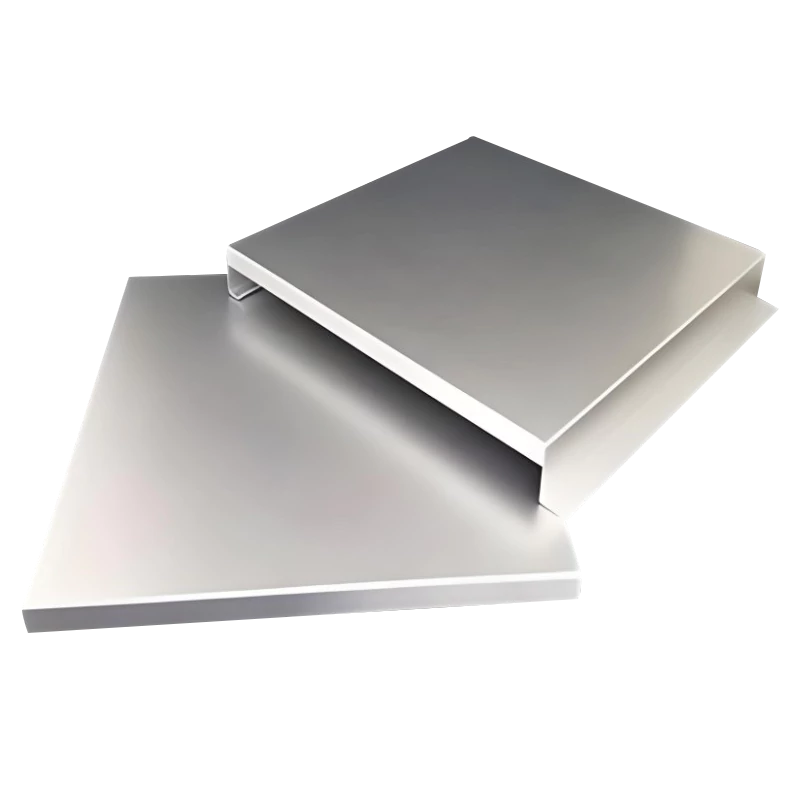

Plate thickness: usually 2mm to 4mm, selected according to different application requirements

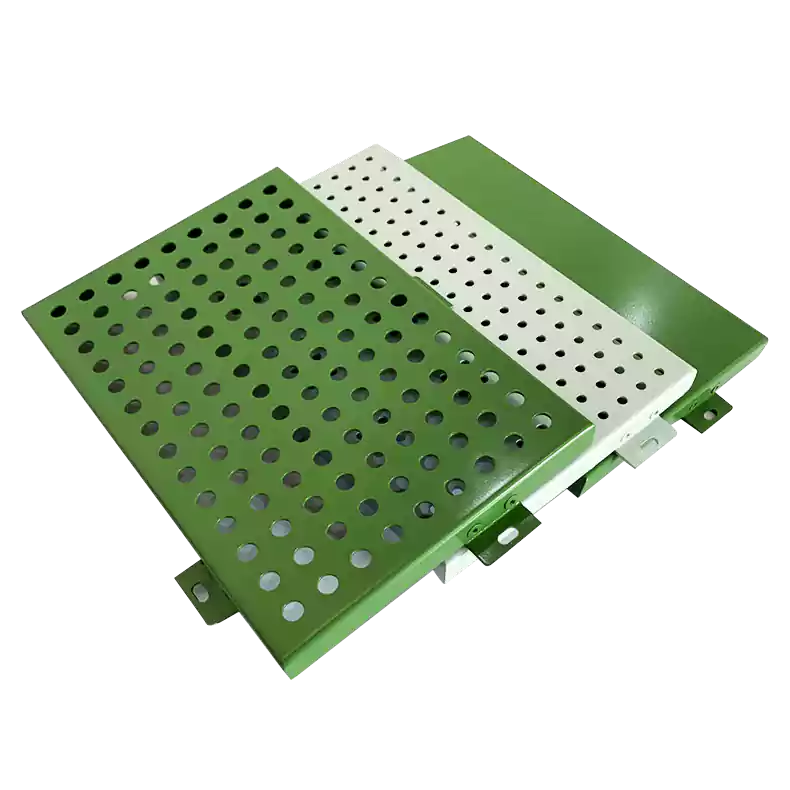

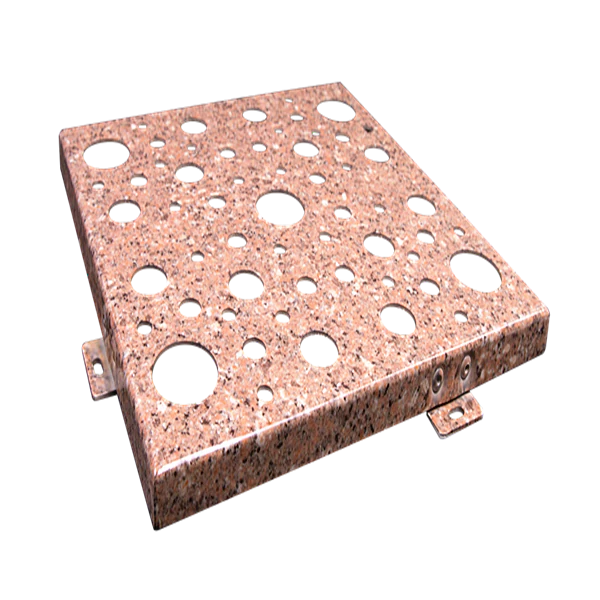

Punching forms: round holes, square holes, long holes and other customized shapes

Aperture: Common aperture range is 1mm to 20mm, and the spacing can be adjusted according to design requirements

Surface treatment: anodizing, electrostatic spraying, fluorocarbon spraying, etc.

Size: Standard size is generally 1200mm x 2400mm, which can be customized according to customer needs

Weight: usually between 3-10kg/m² depending on thickness and size

Products Description

Perforated aluminum veneer is a material widely used in building facades and interior decoration, and is popular for its beautiful, lightweight and corrosion-resistant properties. The following is the introduction and related parameters of punched aluminum veneer:

1. Product introduction

Punched aluminum veneer refers to the formation of holes of various shapes and sizes on aluminum alloy plates through the punching process, which can not only meet the needs of architectural aesthetics, but also have good air permeability and acoustic performance. It is commonly used in facades, curtain walls and indoor partitions of commercial buildings, cultural venues, exhibition centers and other places.

2. Main features

Lightweight and high strength: Aluminum veneer has a low density but high strength and can withstand large wind pressure and other external forces.

Corrosion resistance: The aluminum alloy surface is anodized or spray-coated, which can effectively resist the effects of climate and environment.

Diversified designs: Through different punching methods and patterns, personalized design needs can be achieved.

Easy to maintain: The surface is smooth, easy to clean, and not easy to discolor after long-term use.

Environmentally friendly: Aluminum is recyclable and meets the sustainable development requirements of modern architecture.

3. Main parameters

Material: Aluminum alloy (commonly used aluminum alloy grades are 3003, 5052, etc.)

Plate thickness: usually 2mm to 4mm, selected according to different application requirements

Punching forms: round holes, square holes, long holes and other customized shapes

Aperture: Common aperture range is 1mm to 20mm, and the spacing can be adjusted according to design requirements

Surface treatment: anodizing, electrostatic spraying, fluorocarbon spraying, etc.

Size: Standard size is generally 1200mm x 2400mm, which can be customized according to customer needs

Weight: usually between 3-10kg/m² depending on thickness and size

4. Application fields

Building curtain wall: used for exterior facade decoration to improve the visual effect of the building.

Interior decoration: used as ceiling and wall materials to enhance the beauty of the space.

Advertising signs: can be used to make three-dimensional billboards and signs.

Conclusion

Due to its unique appearance and superior performance, punched aluminum veneer occupies an important position in modern architectural design, meeting the multiple needs of designers and owners for beauty, functionality and environmental protection. Choosing the appropriate punched aluminum veneer can not only improve the overall effect of the building, but also reflect the artistic value of modern architecture.

FAQ

Does the product support customization?

Yes, our products are all factory direct sales and can be customized according to customer needs.

What are the color options for Slatted Acoustic Panel surface?

Melamine Surface、Engineered Wood Surface、Natural Wood Surface、Baseboard Color

What is the thickness of the wood veneer of the Slatted Acoustic Panel?

Our product’s standard wood veneer thickness is 0.45mm and 0.25mm.

How many facets can a Slatted Acoustic Panel have?

Slatted Acoustic Panel has three covers and one cover.