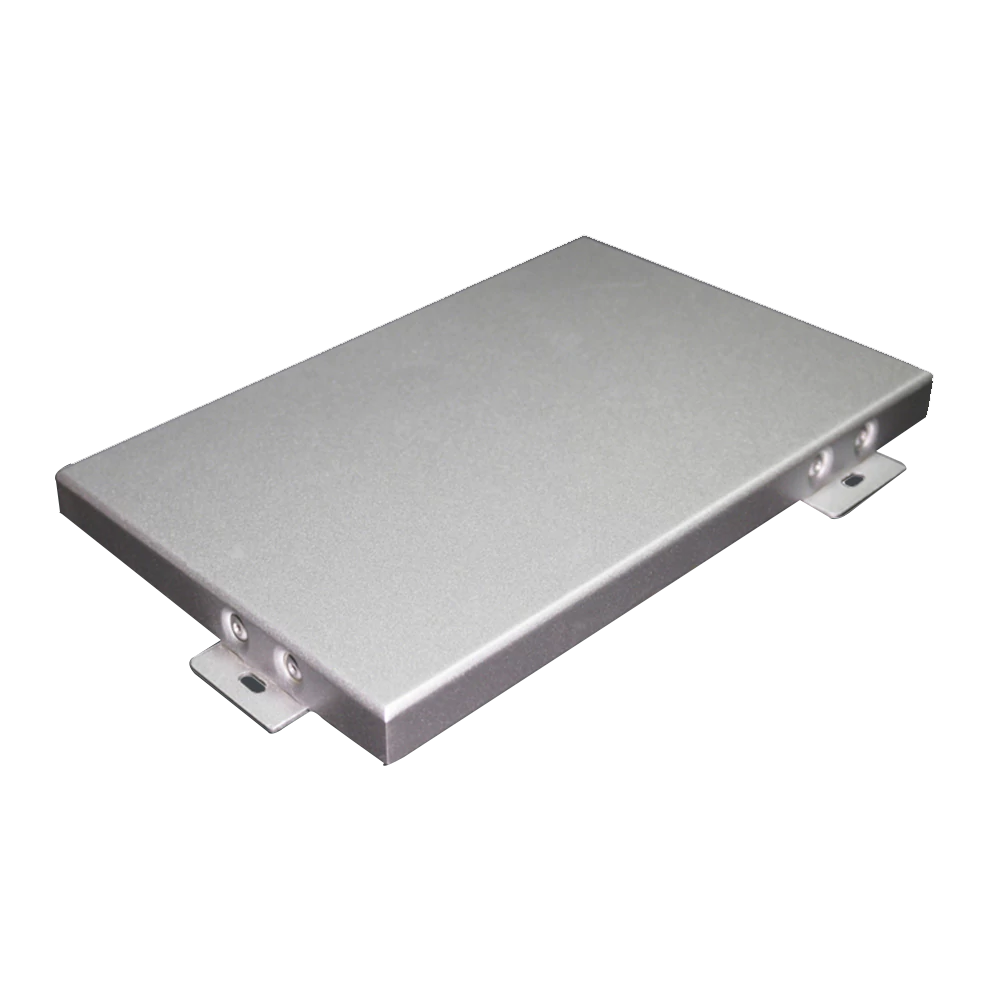

Curtain wall aluminum veneer

Material: high-strength aluminum alloy (such as 1060, 3003, 5052 aluminum alloy)

Thickness: 1.5mm, 2.0mm, 3.0mm (can be customized according to customer needs)

Surface treatment: spraying, anodizing, transfer, coating, etc.

Size: Standard board size is 1220mm x 2440mm (can be customized according to project requirements)

Weight: about 6-8kg/m² (the specific weight depends on the thickness and surface treatment of the aluminum plate)

Temperature resistance range: -50℃ to +80℃

Fire protection grade: Class A (fireproof materials can be provided upon request)

Products Description

Curtain wall aluminum veneer is a new type of building material, which is widely used in facade decoration of modern buildings. It is mainly made of high-strength aluminum alloy, has excellent physical and chemical properties, and is suitable for use in various climate conditions.

Product parameters

Material: high-strength aluminum alloy (such as 1060, 3003, 5052 aluminum alloy)

Thickness: 1.5mm, 2.0mm, 3.0mm (can be customized according to customer needs)

Surface treatment: spraying, anodizing, transfer, coating, etc.

Size: Standard board size is 1220mm x 2440mm (can be customized according to project requirements)

Weight: about 6-8kg/m² (the specific weight depends on the thickness and surface treatment of the aluminum plate)

Temperature resistance range: -50℃ to +80℃

Fire protection grade: Class A (fireproof materials can be provided upon request)

Features

Lightweight and high strength: Aluminum veneer has low density and excellent tensile strength, ensuring structural safety while reducing the burden on the building.

Strong weather resistance: Aluminum veneer with special surface treatment has good corrosion resistance and oxidation resistance, and can adapt to harsh weather conditions.

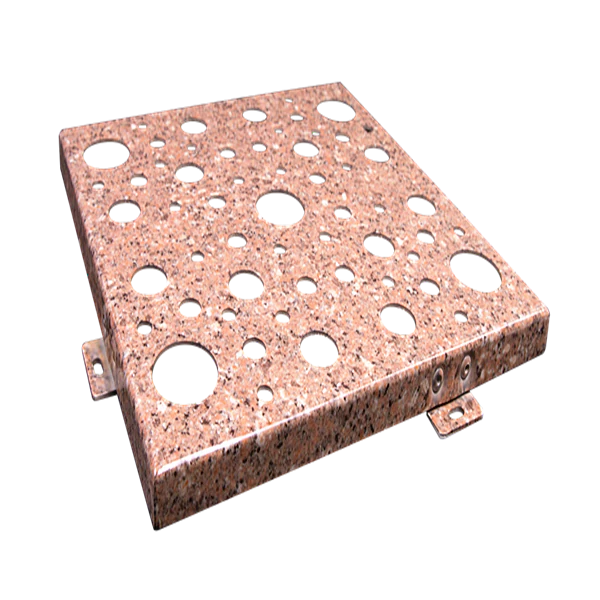

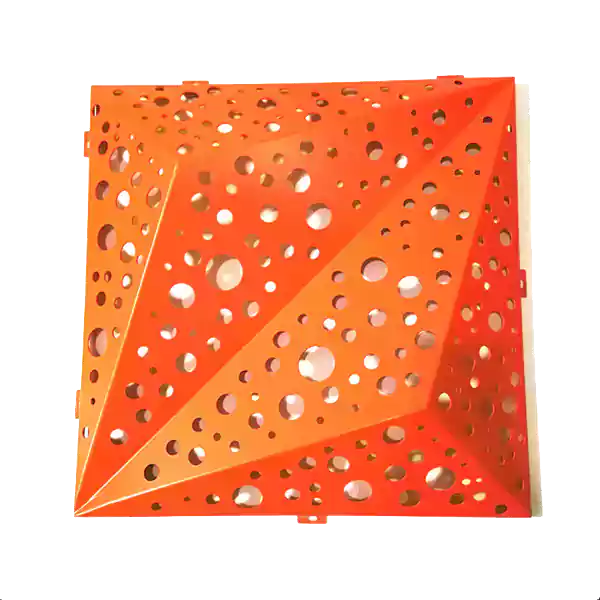

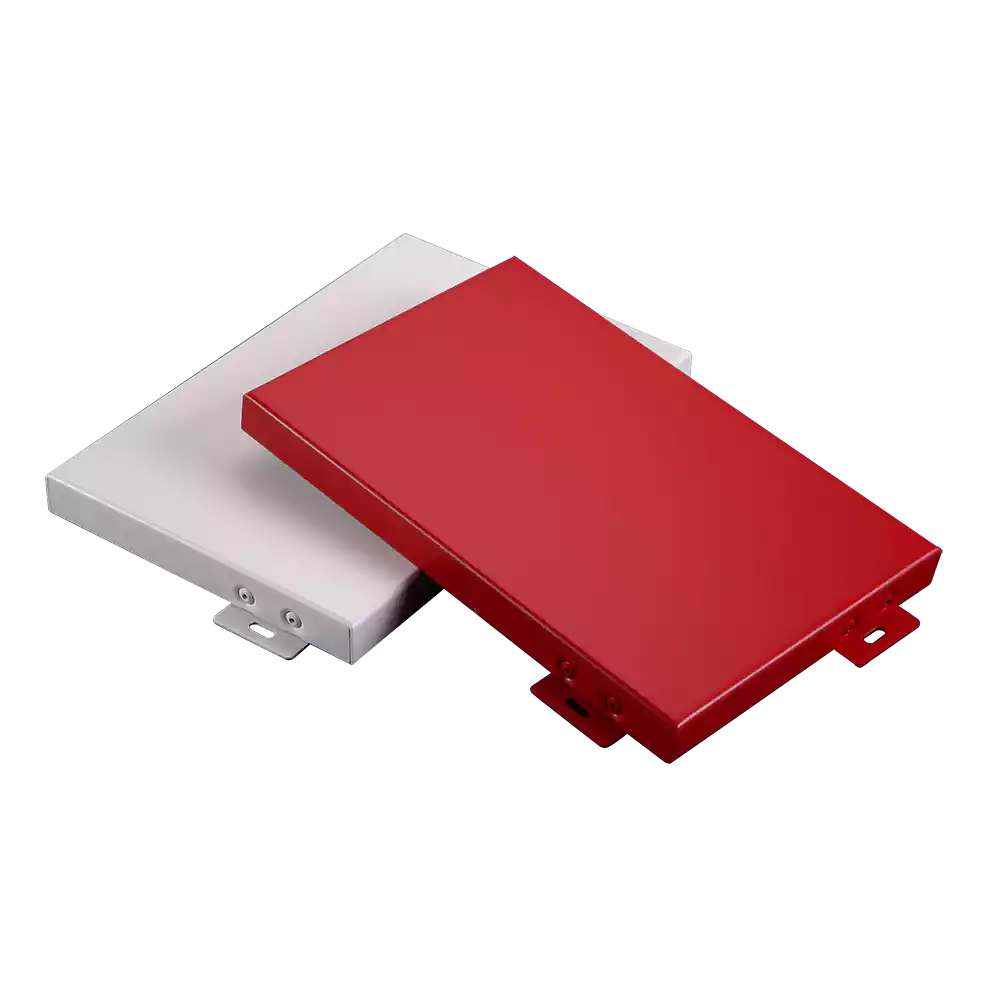

Rich color and texture options: A variety of colors and textures can be customized according to customer needs to meet the needs of different design styles.

Excellent processing performance: Aluminum veneer can be processed in a variety of ways, such as cutting, punching, and bending, to adapt to complex architectural shapes.

Environmental protection: Aluminum is recyclable and meets the requirements of green buildings.

Installation method

Preparation work: Before installation, the installation surface needs to be cleaned to ensure that there is no dust, oil, or other substances that may affect adhesion.

Measurement and marking: According to the design drawings, measure and mark the installation position of the aluminum veneer to ensure accuracy.

Install the keel: According to the size and weight of the aluminum veneer, reasonably lay out the keel structure to ensure stable support.

Fixing the aluminum veneer: Fix the aluminum veneer to the keel through screws, rivets or hangers to ensure its firmness.

Gap treatment: After installation is completed, the gaps between the aluminum veneers are sealed to enhance waterproofness and aesthetics.

Final inspection: Make sure all aluminum veneers are installed flat and securely, and check the overall effect.

Summarize

Curtain wall aluminum veneer has become an ideal choice for modern building facades due to its light weight, high strength, and weather resistance. Through reasonable installation methods, the aesthetics and durability of the building can be effectively improved, and it is an important material for improving the quality of the building.

FAQ

Does the product support customization?

Yes, our products are all factory direct sales and can be customized according to customer needs.

What are the color options for Slatted Acoustic Panel surface?

Melamine Surface、Engineered Wood Surface、Natural Wood Surface、Baseboard Color

What is the thickness of the wood veneer of the Slatted Acoustic Panel?

Our product’s standard wood veneer thickness is 0.45mm and 0.25mm.

How many facets can a Slatted Acoustic Panel have?

Slatted Acoustic Panel has three covers and one cover.