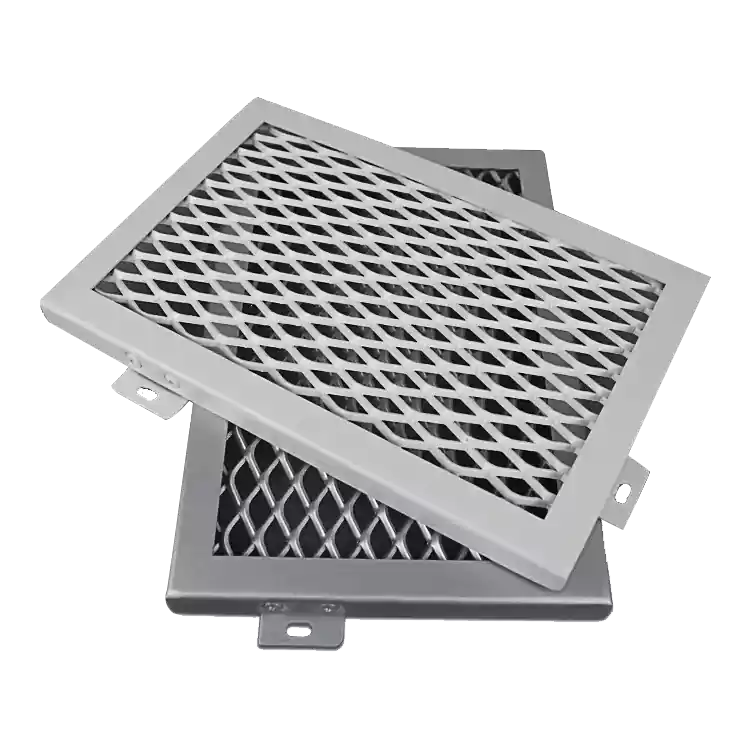

Stretch mesh aluminum veneer

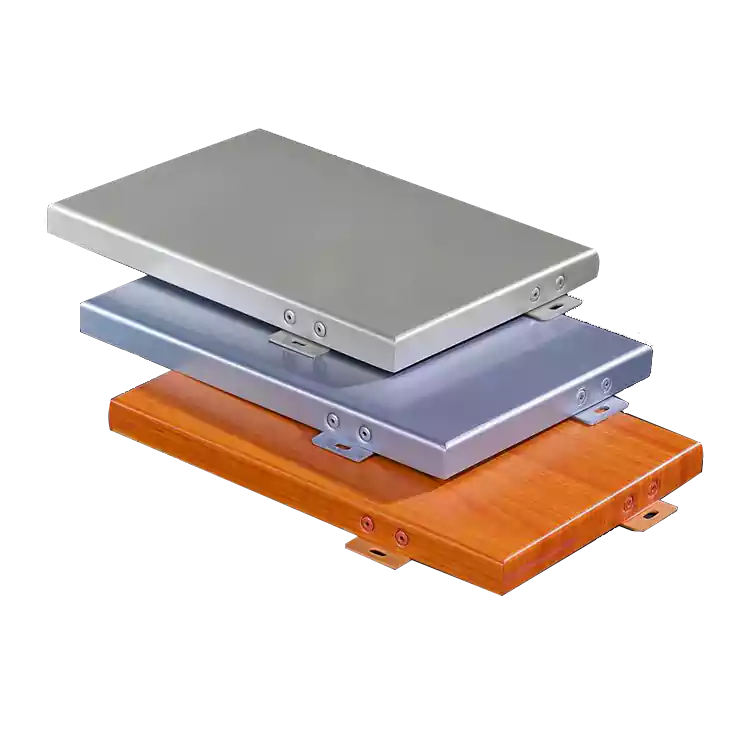

Material: high quality aluminum alloy (common models 3003, 5052, etc.)

Thickness: Conventional thickness is 1.5mm, 2.0mm, 2.5mm, 3.0mm (can be customized)

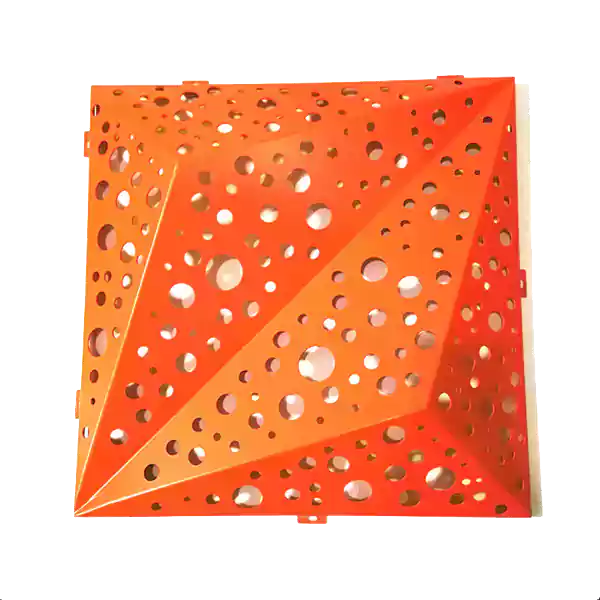

Mesh shape: diamond holes, hexagonal holes, square holes, circular holes, etc. (can be customized according to design requirements)

Mesh size: Conventional apertures are 10mm20mm, 15mm30mm, 20mm*40mm (can be customized)

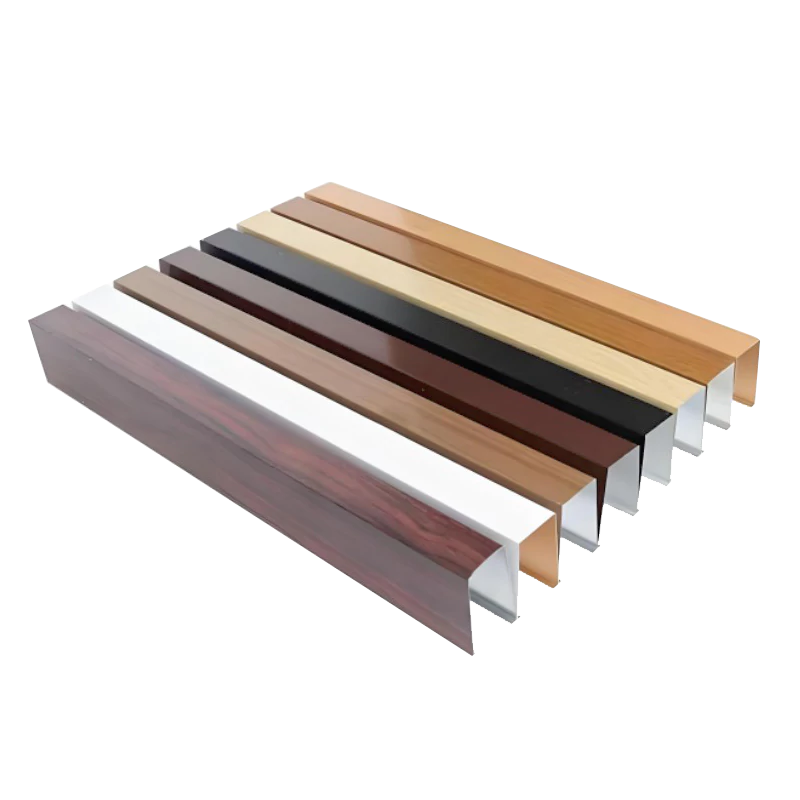

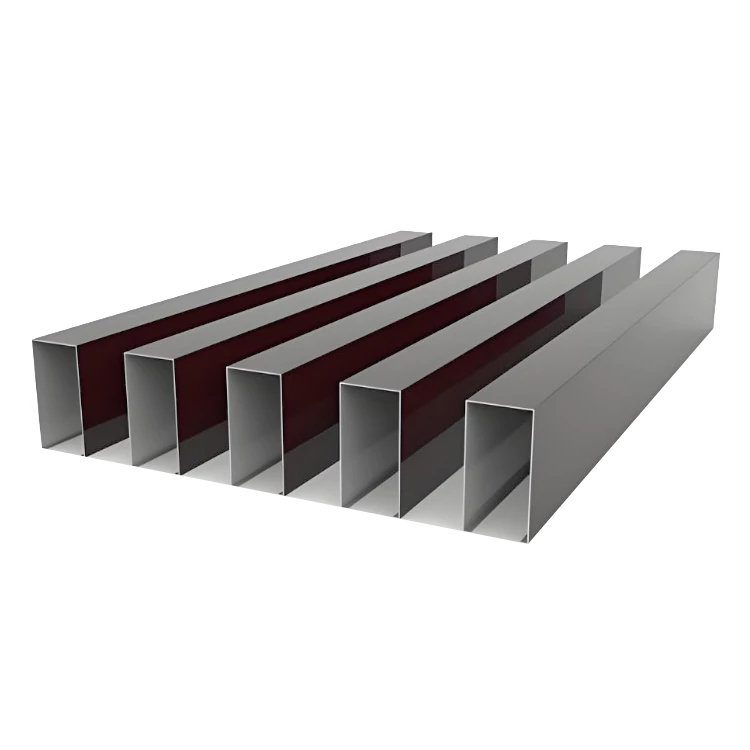

Surface treatment:

Fluorocarbon spraying: strong weather resistance, suitable for outdoor use

Electrostatic powder spraying: rich colors, suitable for indoor and outdoor use

Color: can be customized according to RAL color card

Size: standard size 1200mm*2400mm, can be customized according to needs

Weight: about 5-10kg/㎡ (depending on thickness and hole diameter)