What is an Aluminum Honeycomb Panel?

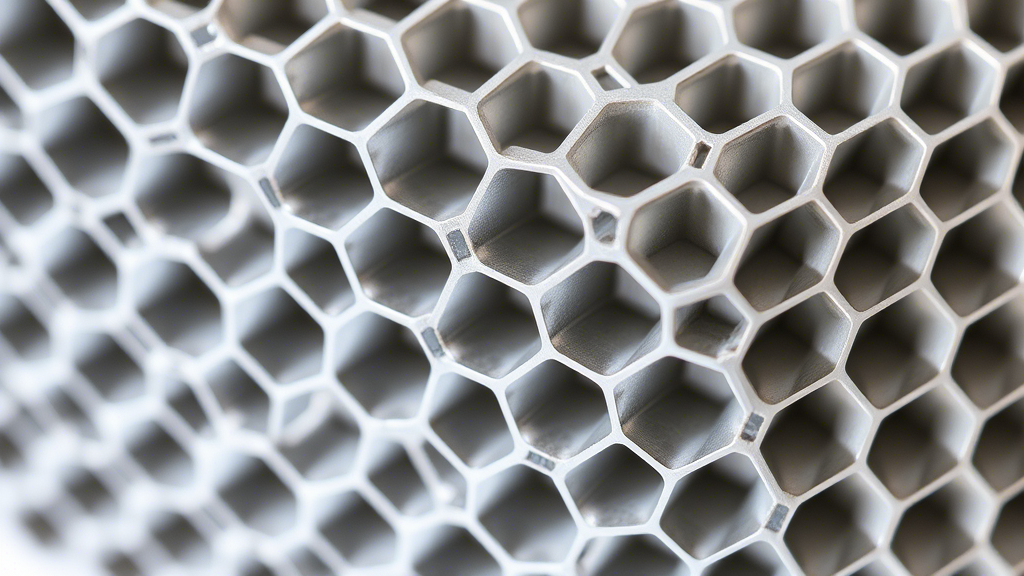

An aluminum honeycomb panel is a composite material that consists of two thin aluminum sheets bonded to a hexagonal aluminum honeycomb core. This unique structure provides exceptional strength-to-weight ratio, making it an ideal material for various industries. The honeycomb core is typically made from aluminum foil, which is expanded and bonded to create a series of hexagonal cells. These cells are then sandwiched between the two aluminum sheets, resulting in a lightweight yet robust panel.

Manufacturing Process of Aluminum Honeycomb Panels

The manufacturing process of aluminum honeycomb panels involves several steps to ensure the highest quality and performance. First, the aluminum foil is cleaned and coated with a bonding agent. The foil is then expanded to form the hexagonal honeycomb structure. Next, the honeycomb core is sandwiched between two aluminum sheets and bonded under heat and pressure. The panels are then cut to size, and any necessary finishing processes, such as painting or anodizing, are applied. This meticulous process ensures that the panels meet the required specifications and standards.

Key Properties of Aluminum Honeycomb Panels

Aluminum honeycomb panels are known for their unique properties, which make them suitable for a wide range of applications. Some of the key properties include:

- High Strength-to-Weight Ratio: The honeycomb structure provides exceptional strength while keeping the weight minimal.

- Rigidity: The panels are highly rigid, making them resistant to bending and deformation.

- Thermal Insulation: The air trapped within the honeycomb cells provides excellent thermal insulation properties.

- Sound Insulation: The structure also offers good sound insulation, reducing noise transmission.

- Fire Resistance: Aluminum is inherently fire-resistant, making the panels suitable for applications where fire safety is a concern.

- Corrosion Resistance: The panels are resistant to corrosion, ensuring long-term durability.

Applications of Aluminum Honeycomb Panels

Aluminum honeycomb panels are used in a variety of industries due to their unique properties. Some of the most common applications include:

- Aerospace: The panels are used in aircraft interiors, flooring, and structural components due to their lightweight and high strength.

- Automotive: They are used in car body panels, roofs, and interior components to reduce weight and improve fuel efficiency.

- Construction: The panels are used in building facades, partitions, and ceilings for their thermal and sound insulation properties.

- Marine: They are used in boat hulls, decks, and interiors for their corrosion resistance and lightweight properties.

- Transportation: The panels are used in train interiors, floors, and ceilings for their durability and fire resistance.

- Industrial: They are used in machinery, equipment, and storage solutions for their strength and rigidity.

Advantages of Using Aluminum Honeycomb Panels

There are several advantages to using aluminum honeycomb panels in various applications:

- Weight Reduction: The lightweight nature of the panels helps reduce the overall weight of structures, leading to improved efficiency and performance.

- Cost-Effective: Despite their advanced properties, aluminum honeycomb panels are cost-effective compared to other materials with similar performance.

- Ease of Installation: The panels are easy to cut, shape, and install, making them convenient for various applications.

- Environmental Benefits: Aluminum is recyclable, making the panels an environmentally friendly choice.

- Versatility: The panels can be customized to meet specific requirements, making them suitable for a wide range of applications.

Challenges and Considerations

While aluminum honeycomb panels offer numerous benefits, there are some challenges and considerations to keep in mind:

- Cost: Although cost-effective, the initial investment in aluminum honeycomb panels can be higher than traditional materials.

- Complex Manufacturing: The manufacturing process is complex and requires specialized equipment and expertise.

- Surface Finish: Achieving a high-quality surface finish can be challenging, and additional processes may be required.

- Maintenance: While the panels are durable, regular maintenance may be required to ensure long-term performance.

Future Trends in Aluminum Honeycomb Panels

The demand for aluminum honeycomb panels is expected to grow in the coming years, driven by advancements in technology and increasing awareness of their benefits. Some of the future trends include:

- Innovative Applications: New applications in emerging industries, such as renewable energy and electronics, are expected to drive demand.

- Enhanced Properties: Research and development efforts are focused on enhancing the properties of the panels, such as improved thermal and sound insulation.

- Sustainable Manufacturing: There is a growing focus on sustainable manufacturing practices, including the use of recycled materials and energy-efficient processes.

- Customization: The ability to customize panels to meet specific requirements is expected to become more prevalent, offering greater flexibility for various applications.

Conclusion

Aluminum honeycomb panels are a versatile and high-performance material that offers numerous benefits across a wide range of industries. Their unique properties, such as high strength-to-weight ratio, rigidity, and thermal insulation, make them an ideal choice for applications in aerospace, automotive, construction, marine, transportation, and industrial sectors. While there are some challenges and considerations, the advantages of using aluminum honeycomb panels far outweigh the drawbacks. As technology continues to advance, the demand for these panels is expected to grow, driven by innovative applications, enhanced properties, and sustainable manufacturing practices.