Aluminum honeycomb ceiling panel

Material: aluminum alloy (commonly used are 1060, 3003, etc. series)

Thickness: usually between 0.5mm and 1.5mm, depending on needs

Size: Standard sizes are 600mm x 600mm, 600mm x 1200mm, which can also be customized according to customer needs

Density: The aluminum honeycomb structure makes it light in weight, and the density is generally 3-4 kg/m²

Compressive strength: can reach 300-400 kg/m², with good load-bearing capacity

Sound insulation performance: usually 30-40 dB, suitable for places that require a quiet environment

Products Description

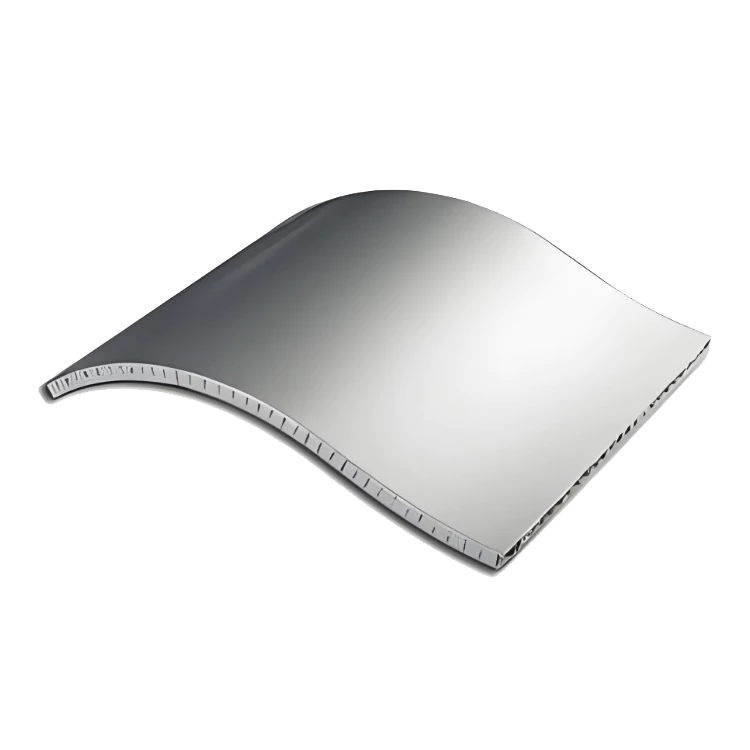

Aluminum honeycomb ceiling panels are a lightweight, high-strength building material widely used in commercial, office and public buildings. Its main parameters include: thickness is usually 10-25mm, weight is about 5-10kg/m², and compressive strength can reach 200-300kPa. In terms of surface treatment, aluminum honeycomb panels often use spraying, oxidation and coating processes to improve Durability and beauty.

In terms of technology, aluminum honeycomb ceiling panels combine aluminum alloy plates with honeycomb structures to form excellent sound insulation and heat insulation properties. Application fields include airports, stations, shopping malls and offices, etc., which can not only provide good visual effects, but also have strong practicality. By further understanding the characteristics and advantages of aluminum honeycomb ceiling panels, we can help you make a better choice.

1. Parameters

Material: aluminum alloy (commonly used are 1060, 3003, etc. series)

Thickness: usually between 0.5mm and 1.5mm, depending on needs

Size: Standard sizes are 600mm x 600mm, 600mm x 1200mm, which can also be customized according to customer needs

Density: The aluminum honeycomb structure makes it light in weight, and the density is generally 3-4 kg/m²

Compressive strength: can reach 300-400 kg/m², with good load-bearing capacity

Sound insulation performance: usually 30-40 dB, suitable for places that require a quiet environment

2. Application

Aluminum honeycomb ceiling panels are widely used in the following places:

Commercial spaces: such as shopping malls, hotel lobbies, restaurants, etc., to enhance the overall aesthetics and luxury

Office building: Provides a modern office environment with good sound insulation effect

Airports and stations: Suitable for suspended ceilings in large spaces due to its light weight and corrosion resistance

Exhibitions and museums: able to meet high design requirements and facilitate installation and maintenance

Healthcare facilities: Suitable for places such as hospitals due to its ease of cleaning and antimicrobial properties

3. Craftsmanship

The production process of aluminum honeycomb ceiling panels mainly includes the following steps:

Material preparation: Choose high-quality aluminum alloy materials to ensure strength and corrosion resistance

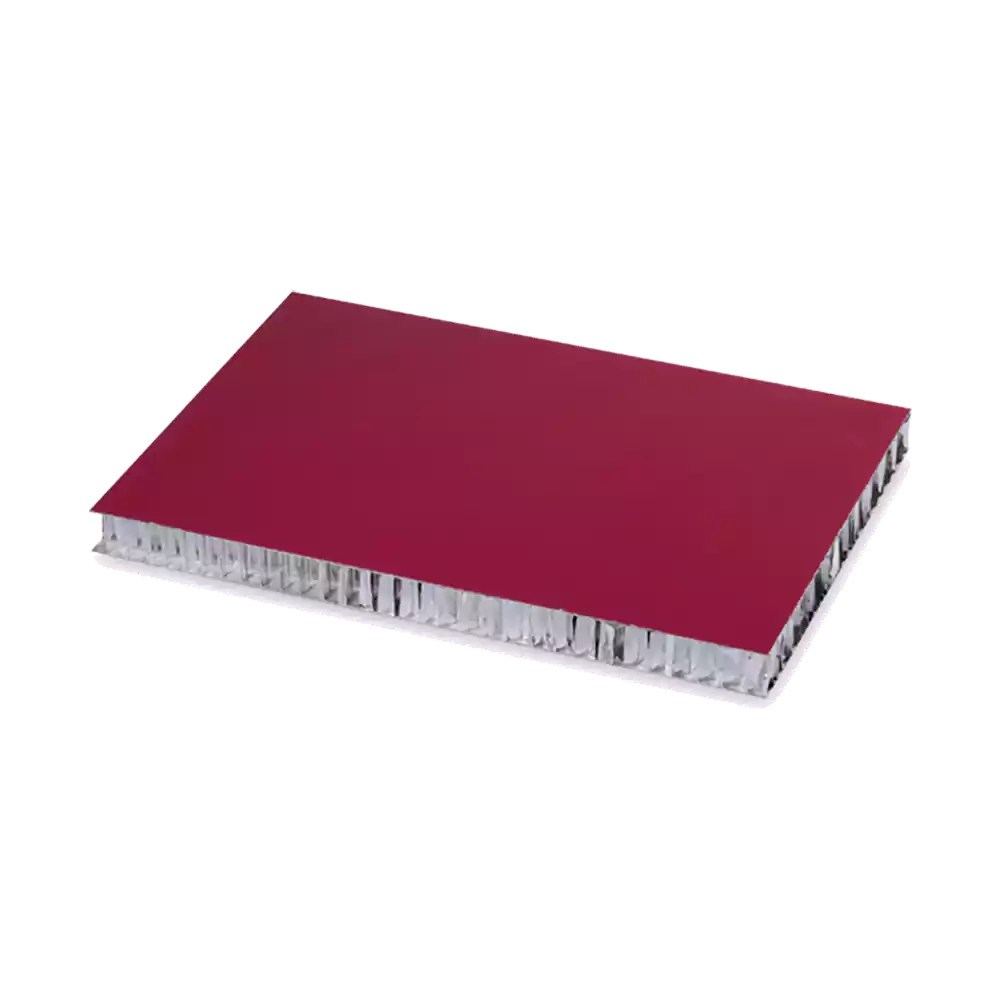

Honeycomb core manufacturing: Using hot press forming process, the aluminum honeycomb structure is pressed and formed.

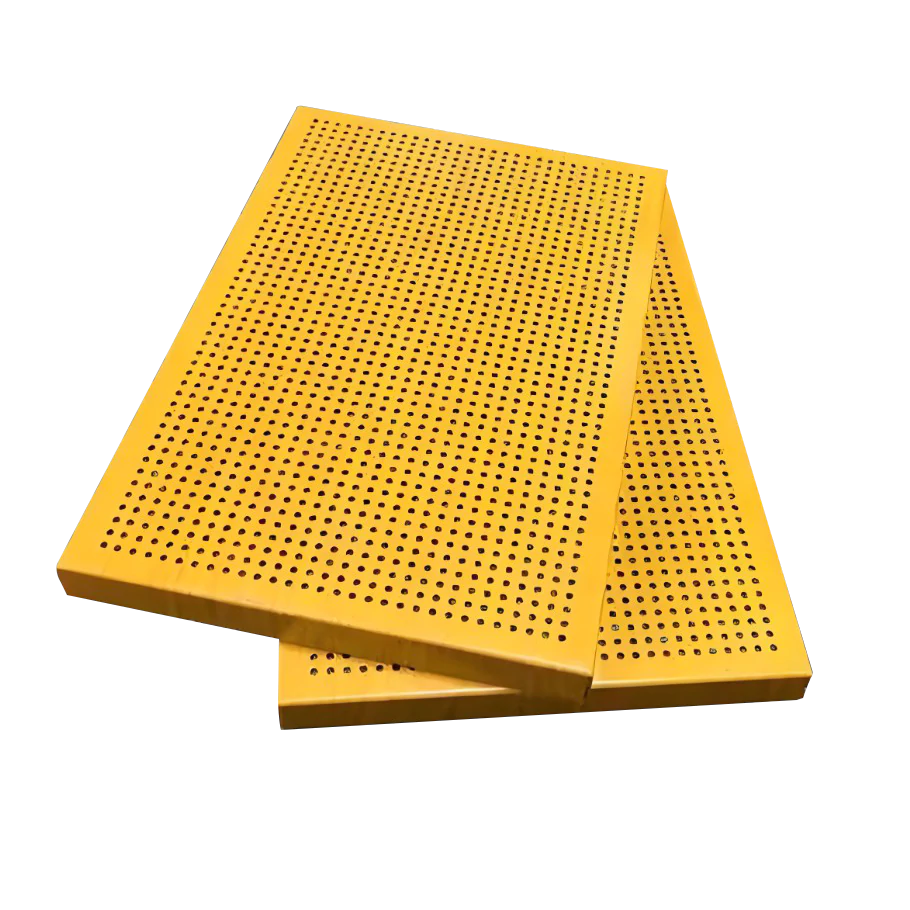

Aluminum panel processing: Cutting, punching, folding and other processes are performed on aluminum panels to adapt to different installation needs.

Assembly: Combine the honeycomb core with the aluminum panel to form an integrated ceiling panel

Quality inspection: Strict quality inspection of finished products to ensure compliance with standards

4. Surface treatment

The surface treatment of aluminum honeycomb ceiling panels is an important step in improving their appearance and durability. Common surface treatment processes include:

Electrostatic spraying: The paint is evenly sprayed on the surface of the aluminum plate through electrostatic adsorption technology, providing a variety of color options and strong wear resistance

Anodizing: Improves the corrosion resistance and wear resistance of the aluminum surface and forms a protective film

Wood grain film: Through film technology, the wood grain effect is simulated and the natural beauty is increased.

Mirror polishing: Make the aluminum surface as smooth as a mirror and highly reflective, suitable for high-end places

in conclusion

Aluminum honeycomb ceiling panels have become an indispensable decorative material in modern buildings due to their superior performance and wide range of applications. With the development of science and technology, its process and surface treatment technology will continue to improve, further enhancing its market competitiveness. Whether it is a commercial or home environment, aluminum honeycomb ceiling panels can bring unique beauty and practicality to the space.

FAQ

Does the product support customization?

Yes, our products are all factory direct sales and can be customized according to customer needs.

What are the color options for Slatted Acoustic Panel surface?

Melamine Surface、Engineered Wood Surface、Natural Wood Surface、Baseboard Color

What is the thickness of the wood veneer of the Slatted Acoustic Panel?

Our product’s standard wood veneer thickness is 0.45mm and 0.25mm.

How many facets can a Slatted Acoustic Panel have?

Slatted Acoustic Panel has three covers and one cover.