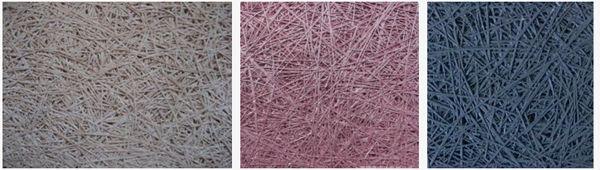

1. Wood wool sound-absorbing panels

Wood wool sound-absorbing panels are made from poplar wood fiber as raw material, combined with a unique inorganic hard cement binder, using a continuous operation process and under high temperature and high pressure conditions. The outer surface has a filamentous texture, which is rough and unique, and has good sound absorption. The surface can be painted and painted to achieve the desired effect.

Wood wool sound-absorbing panels have a strong structure, are impact-resistant, are easy to cut, and have simple installation methods. The boards are processed from sustainable raw materials, and the process meets environmental requirements. They do not contain any ingredients harmful to the human body. They are moisture-proof, energy-saving, heat-insulating, and have a long life. Because they are mainly processed from wood, they have low thermal conductivity, so they have great Strong thermal insulation performance.

In addition to the square wood wool sound-absorbing panels, there is another hexagonal board, sprayed with various colors of paint, which is very suitable for decorating the wall. After splicing, it has strong lines and rich layers.

Wood wool sound-absorbing panels, specifications 600X600mm, 1200X2400mm, 600X1200mm, thickness 5mm, market price is about 40~130 yuan/sheet; hexagonal side length is generally 120mm, price is about 25~85 yuan/sheet .

2. Mineral wool sound-absorbing panels

Mineral wool sound-absorbing panels are made of granular cotton as the main raw material, mixed with other additives, high-pressure steaming, extrusion and cutting. They are fire-proof and sound-absorbing and do not contain asbestos. No needle-like dust will appear and it is harmless to the human body.

The moisture-proof agent added inside the mineral wool board not only enhances the resistance of the surface fibers, effectively stabilizes the cement, maintains the strength of the board, and can adjust the room temperature and improve the environment.

Mineral wool board is made of mineral fiber cotton. It has good sound absorption and heat insulation effects, is non-flammable, moisture-proof and easy to clean. The surface has patterns such as knurling and relief effects. There are generally irregular holes on the surface.

Mineral wool boards are most suitable for use in shopping malls and office spaces. They can absorb and decompose toxic and harmful gases and improve the environment. The specifications are generally 600X600mm and the thickness is 16mm. The general market price is about 20~60 yuan/piece.

3. Fabric sound-absorbing panels

Fabric sound-absorbing panels are exquisitely processed based on acoustic principles and consist of soft fabric (fireproof fabric) facings, frames and sound-absorbing cotton.

Fabric sound-absorbing panels—the core material is fire-resistant Class A centrifugal glass wool. As an acoustic material that has been widely used all over the world for a long time, centrifugal glass wool has excellent sound absorption properties.

Fabric sound-absorbing panels are available in a variety of colors and patterns of facing fabrics, or the facing fabrics can be provided by customers. And the material of the facing fabric and frame can be adjusted according to the acoustic decoration or the owner’s requirements. Fabric sound-absorbing panels are available in a variety of colors and patterns. They are flame retardant, fireproof, dust-free, highly decorative, and simple to construct (glue or keel). Commonly used corner processing methods are square corners, rounded corners, beveled corners, large beveled corners, etc. Common specifications are 1200X600mm, 600X600mm, 600X800mm, etc., and thicknesses are 25mm and 50mm.

Fabric sound-absorbing panels are mainly used in hotels, restaurants, offices, theaters, recording studios, studios, conference rooms, dance halls, bowling alleys, home theaters and other medium and high-end decoration places that require sound quality treatment.

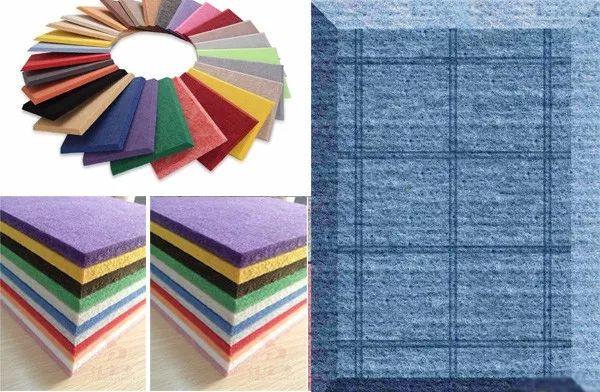

4. Polyester fiber sound-absorbing panels

Polyester fiber sound-absorbing panels are made of 100% polyester fiber that has been heat-pressed with high technology and made into a cocoon-cotton shape. It is heat-treated to achieve density diversity and ensure ventilation. It is one of the outstanding products among sound-absorbing materials and heat-insulating materials. It has the advantages of sound absorption, environmental protection, flame retardant, heat preservation, heat insulation, anti-mildew, easy to cut, can be put together, good stability and independence, and simple construction.

The article is collected from the Internet and is for sharing and reading only. It does not represent the views of this site. If it infringes upon your rights, please contact us to delete it!