The structure of the Punched Aluminum Honeycomb Panel is a perforated panel and a perforated back panel. It relies on high-quality adhesive to directly bond the aluminum honeycomb core to form an aluminum honeycomb sandwich structure. A layer of sound-absorbing cloth is pasted between the honeycomb core, the panel and the back panel.

Because the honeycomb core in the honeycomb aluminum panel is divided into numerous closed chambers, it prevents air flow, hinders sound waves, increases the sound absorption coefficient (can reach more than 0.9), and at the same time increases the strength of the panel itself, so that the size of a single panel can be Making it bigger further increases the degree of design freedom. According to the indoor acoustic design, different perforation rate designs can be carried out to control the sound absorption coefficient of the combined structure within a certain range, which not only achieves the design effect, but also reasonably controls the cost.

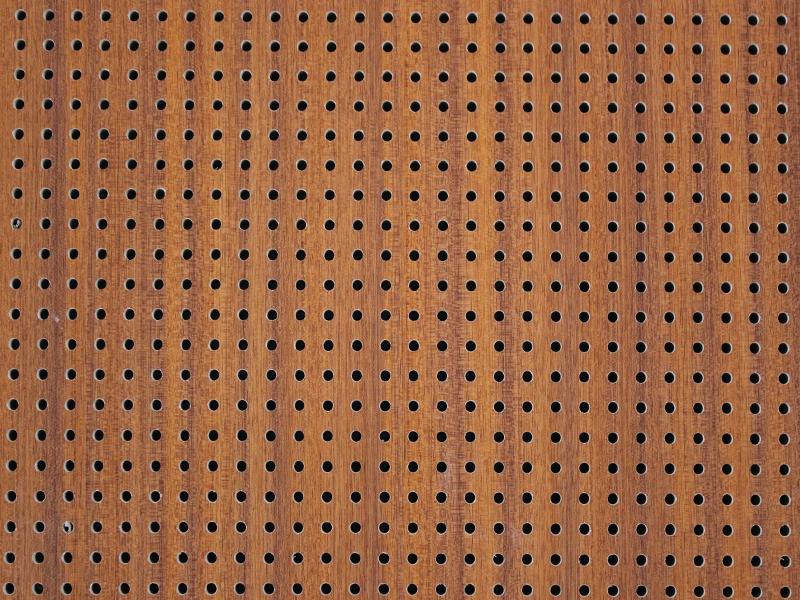

By controlling the perforation aperture and spacing, the perforation rate can be changed according to customer requirements. The perforation rate is ≦30%. The apertures generally use ∮2.0, ∮2.5, ∮3.0 and other specifications. The perforation requirements for the back panel are the same as those for the panel. The sound-absorbing cloth is made of high quality Non-woven fabrics and other sound-absorbing materials.

The article is collected from the Internet and is for sharing and reading only. It does not represent the views of this site. If it infringes upon the rights of a third party, please contact us to delete it!